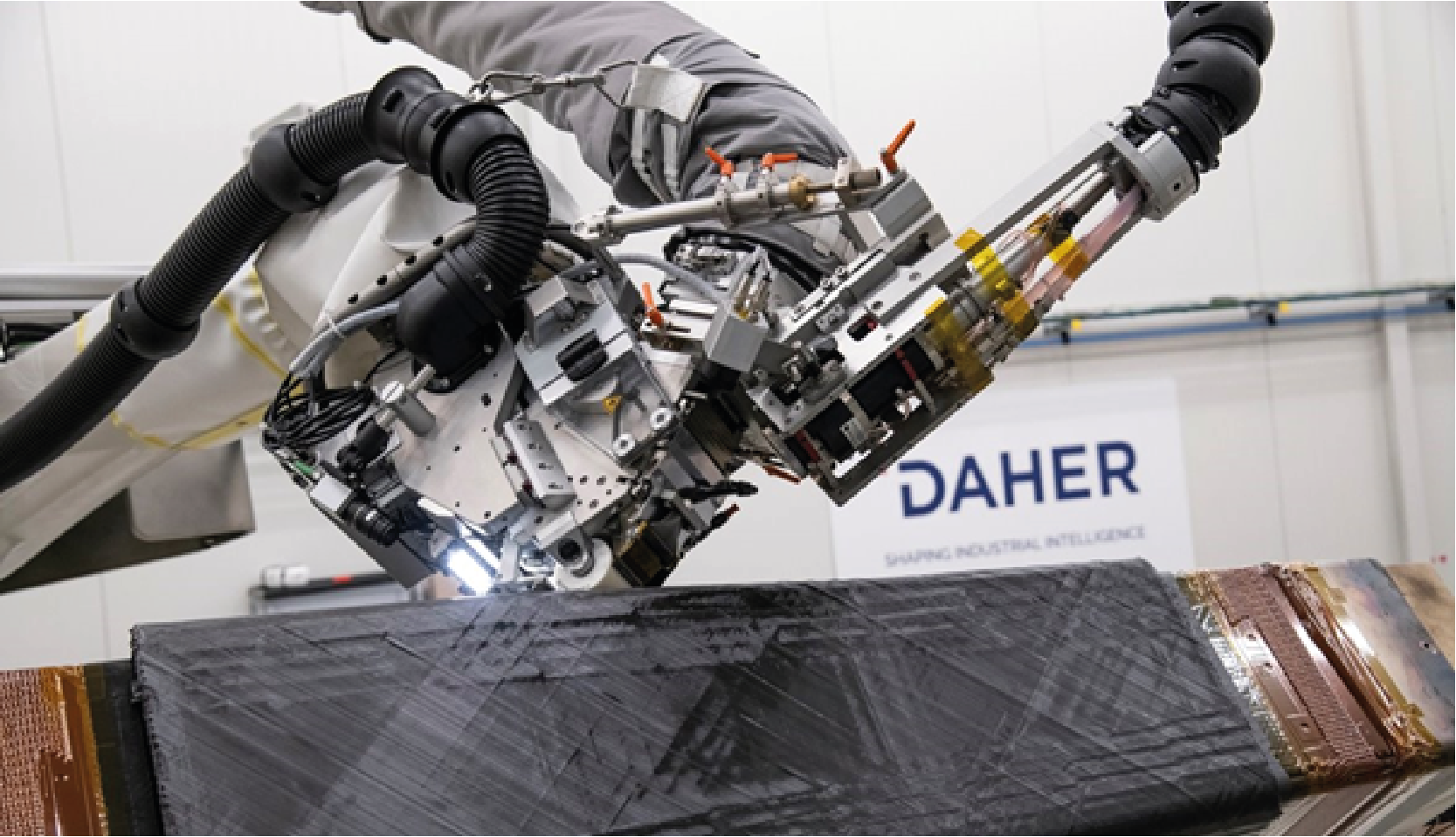

Advanced environmental monitoring at an aircraft coating production facility – DAHER – France

Year

2021

Location

CORNEBARRIEU - FRANCE

Sector(s)

Heavy and manufacturing industries

Related sensor(s)

POD2

Issues

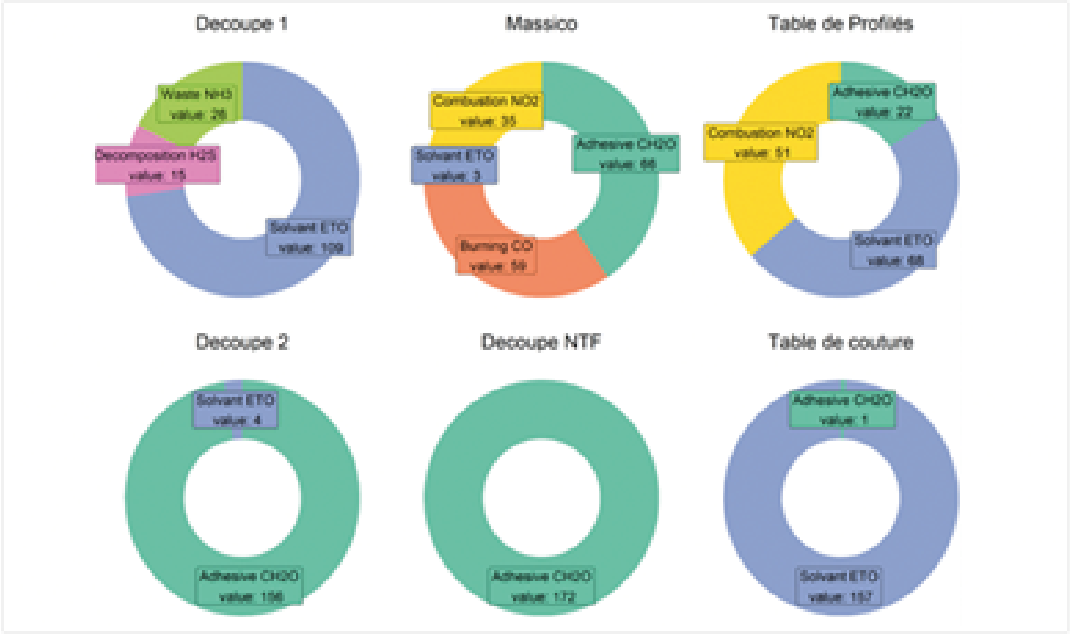

To address the specific needs of an industry in Cornebarrieu, specializing in aircraft coatings production, an environmental monitoring project was initiated. The primary goal was to create a detailed sensory map, identify odor nuisances, and locate the sources of these nuisances. Additionally, a thorough analysis of air quality at various workstations was essential to ensure optimal working conditions.

SOLUTION

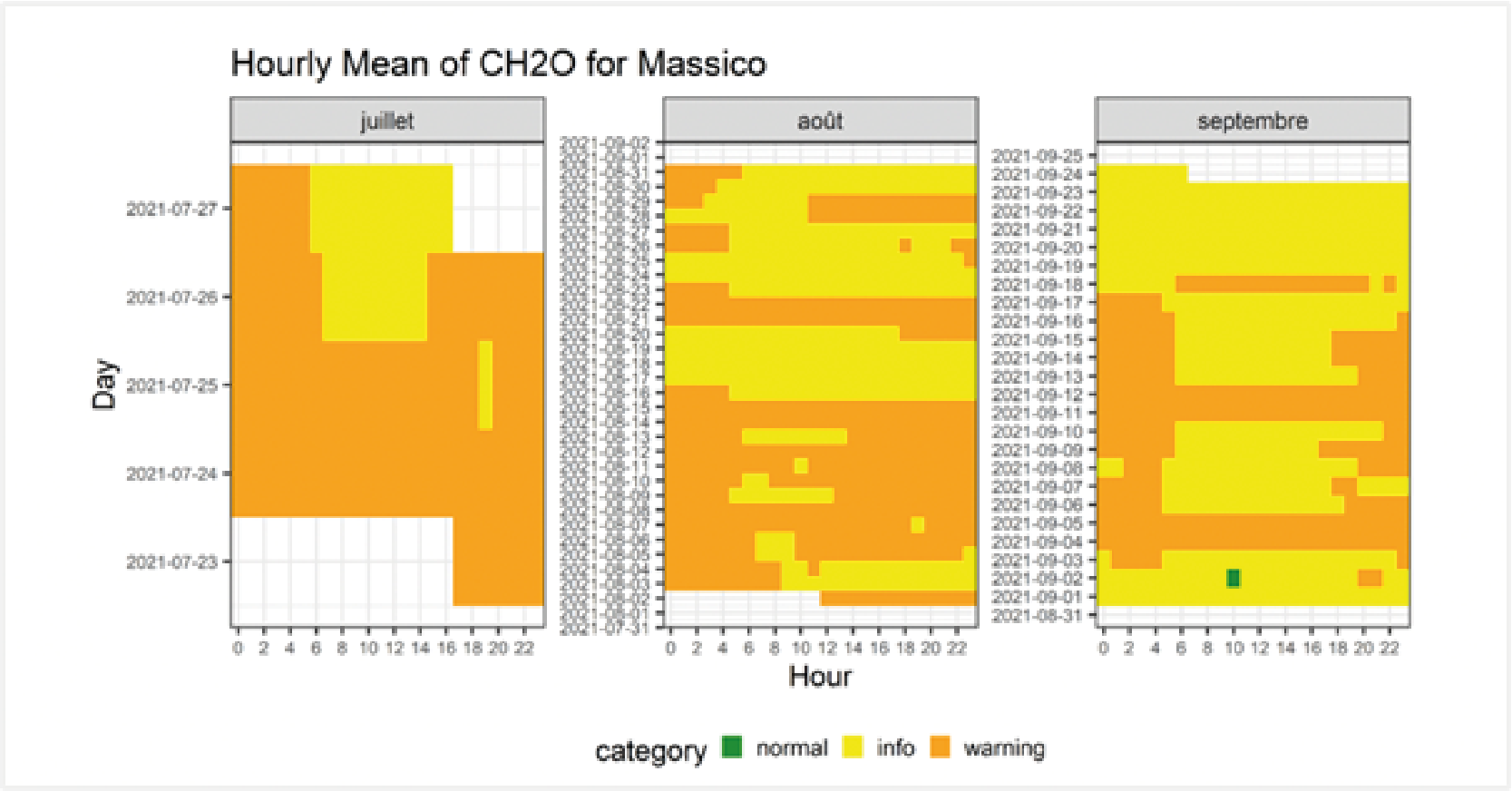

The project incorporated Ellona’s POD2, a multifunctional device capable of measuring various environmental parameters. In July 2021, six POD2 units were installed to collect high-frequency data over a four-month period.

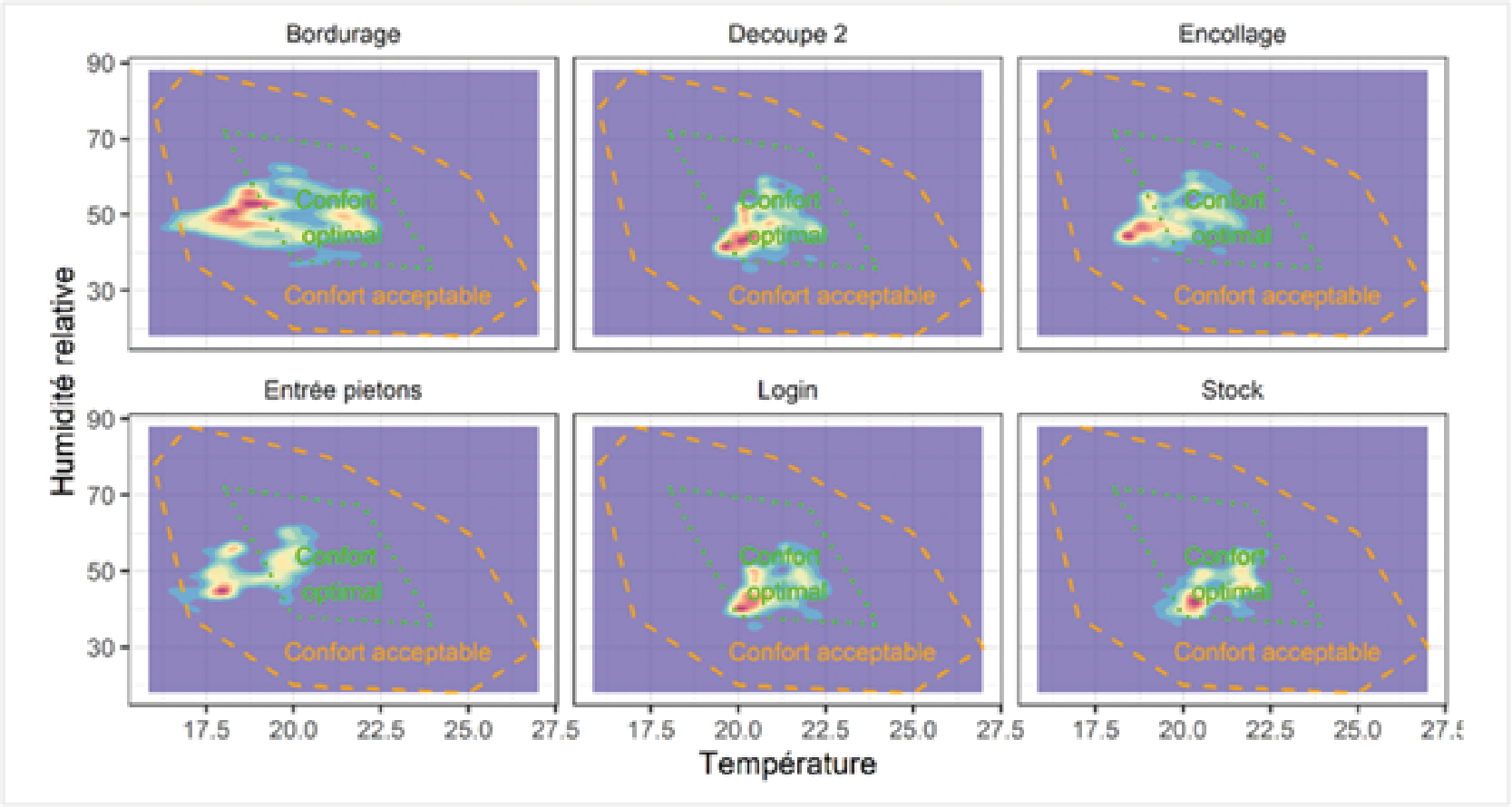

Installation phases involved relocating the POD2 units to monitor different workstations, measuring parameters such as temperature, humidity, noise levels, as well as specific Ellona indices to assess comfort and viral contamination. All results were accessible in real time through the EllonaSoft interface, allowing for proactive and reactive management of environmental conditions.

The use of Ellona indices enabled accurate assessment of comfort, viral contamination, and odor nuisances. Recommendations were made, including the installation of preventive ventilation in areas with formaldehyde accumulation, based on the obtained results. This integrated approach aimed to significantly improve worker well-being by optimizing their working environment.

KEY RESULTS

- Accurate mapping of the impacts of activities on working conditions, enabling targeted intervention management.

- Positive correlation between proposed installations and improvement in air quality, demonstrating the effectiveness of the measures taken.

- Identification of previously unknown isolated events, facilitating the rapid implementation of remediation solutions.

- Substantial improvement in working conditions in the workshop due to continuous monitoring and proactive data analysis.

This project with the industry in Cornebarrieu not only enhanced the factory’s environmental management but also raised the standard of worker well-being, illustrating the concrete benefits of advanced and proactive working condition monitoring.