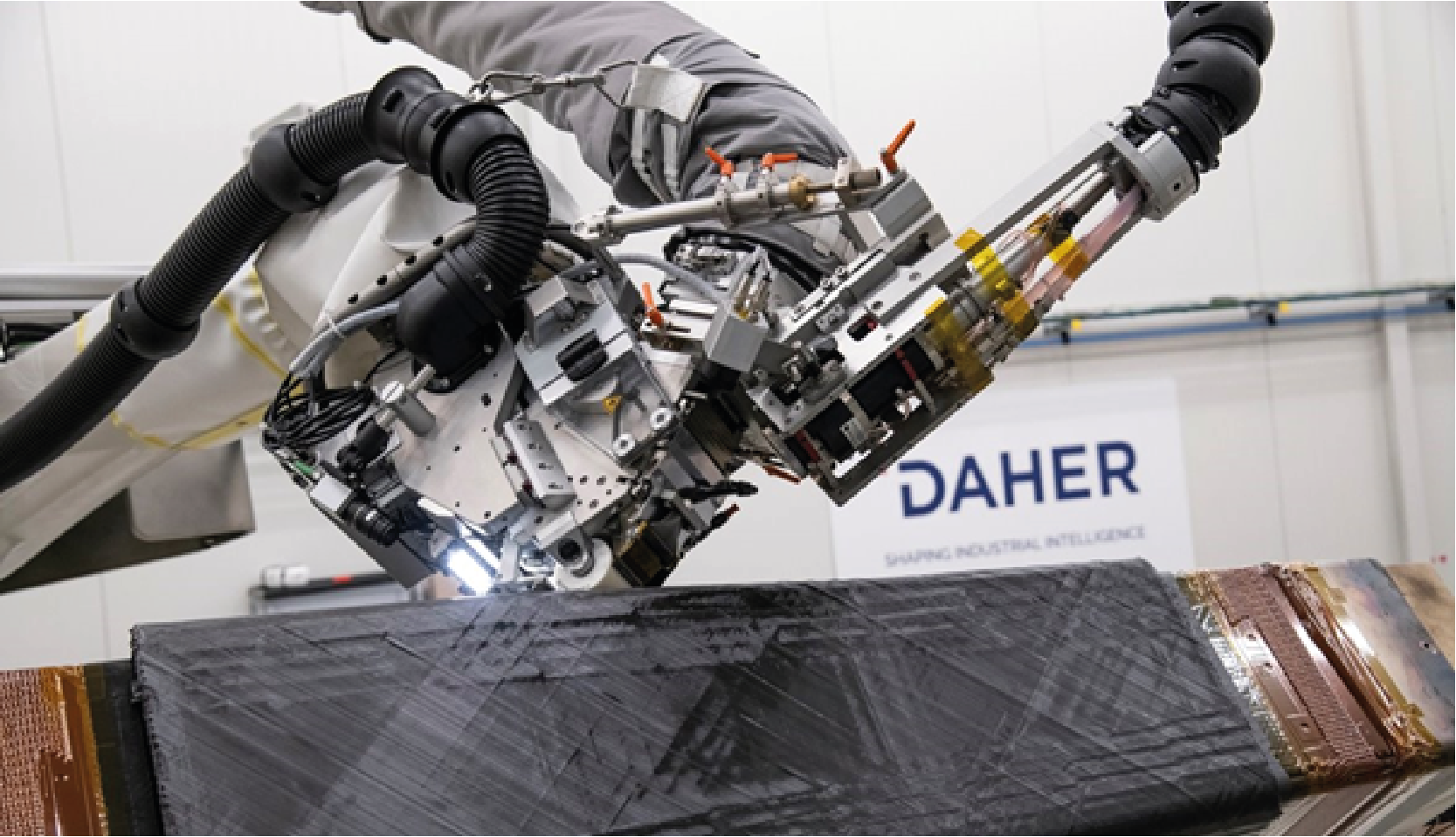

Complex emission sources that we address

Heavy and manufacturing industries are significant contributors to atmospheric emissions, with complex sources both inside their facilities and in their surroundings. These sources can be categorized into four main areas:

- Emissions from production processes: These emissions arise directly from manufacturing activities, such as workshops, factories, and refineries. They include greenhouse gases (GHGs) and other pollutants produced by chemical reactions and industrial processes.

- Emissions from support and maintenance equipment: This category covers pollutants emitted by essential equipment such as boilers, compressors, cooling systems, and incinerators used for waste treatment.

- Pollution from fixed infrastructure: This includes emissions from heating, ventilation, and air conditioning (HVAC) systems, as well as power generation facilities that provide electricity for industrial operations.

- Emissions from vehicle traffic and logistics: These emissions come from the transportation of raw materials and finished products, including those generated by service and delivery vehicles.

These diverse sources collectively contribute to significant atmospheric emissions associated with industrial activities. Moreover, air quality within industrial environments, such as production areas and workshops, is a critical concern for the health and safety of employees.

In this context, Ellona’s environmental monitoring systems are instrumental. By offering precise tracking of particles, gases, odors, and noise, Ellona enables industrial stakeholders to make informed decisions that enhance air quality, optimize operational processes, and mitigate environmental impacts.

Ellona develops tailored solutions for the industrial sector.

Ellona offers a comprehensive range of real-time monitoring technologies, such as the WT1 Pro, WT1 Lite, POD2, and our EllonaSoft platform, specifically designed for heavy and manufacturing industries.

These tools provide precise quantification and identification of emission sources, addressing both peripheral and direct sources, whether they are channelled or surface-based.

This enables the implementation of targeted corrective measures to reduce environmental impacts while ensuring proactive environmental management, rigorous regulatory compliance, and a strengthened commitment to economic and environmental sustainability.

Our commitments

to the heavy and manufacturing industries

High-precision environmental monitoring:

- Measure atmospheric emissions in real-time.

- Implement a robust monitoring system for effective emission management.

- Diagnose emission issues accurately and provide immediate alerts.

- Utilize advanced technologies to monitor gases, particles, odors, and noise.

- Anticipate pollutant dispersion patterns for appropriate preventive actions.

- Objectively identify pollutant compounds for data-driven solutions.

- Conduct comprehensive analysis at site peripheries and source levels.

Regulatory compliance:

- Ensure full adherence to environmental standards for noise, odor, gas, and particulate emissions.

Industrial process optimization:

- Use data to continuously improve processes and reduce emissions.

Quality of life improvement:

- Enhance air quality and working conditions, as well as the quality of life for affected populations.

Risk management and safety:

- Assess and mitigate environmental and health risks associated with emissions.

- Ensure a safe working environment through continuous monitoring.

Technical support and customer service:

- Provide optimal assistance for the implementation and use of solutions.

Data transparency and reliability:

- Offer transparent and reliable data to support informed decision-making.

Regulatory standards for the industrial sector

The parameters monitored and the limit value standards for atmospheric emissions in heavy or processing industries are determined by local regulations and the specific characteristics of each industrial site. Key regulations include:

1- EUROPEAN INDUSTRIAL EMISSIONS DIRECTIVE (IED)

It aims to reduce atmospheric emissions from industrial installations to protect air quality and human health, by promoting the use of Best Available Techniques (BAT) to minimize emissions. For example:

- For nitrogen oxides (NOx): emission limit value (ELV) of 200 mg/Nm³ for large combustion plants..

- For fine particulate matter (PM): emission limit value (ELV) of 10 mg/Nm³ for biomass combustion installations.

2- NATIONAL AIR QUALITY STANDARDS

National air quality standards are regulations set by individual countries to control pollutant concentrations in the air, thereby protecting public health and the environment. These standards typically specify the maximum allowable concentrations for various pollutants, including particulates, gases, and other substances. The details may vary from one country to another but generally include:

- Fine particulates (PM10, PM2.5): Limits are often set for daily and annual averages. For example, a common standard might be 50 µg/m³ for PM10 over a 24-hour period and 40 µg/m³ as an annual average, and 25 µg/m³ for PM2.5 over a 24-hour period and 20 µg/m³ as an annual average.

- Nitrogen dioxide (NO₂): Limits may be set for hourly and annual averages. A typical standard could be 180 µg/m³ for an hourly average and 40 µg/m³ annually.

- Sulfur dioxide (SO₂): Standards often cover short-term (hourly) and long-term (daily or annual) exposures. For example, a standard might be 350 µg/m³ for an hourly average and 125 µg/m³ for a daily average.

- Carbon monoxide (CO): Standards typically cover both short-term and long-term exposures. For example, a standard might be 10 mg/m³ for an hourly average and 5 mg/m³ for an eight-hour average.

- Ozone (O₃): Standards may be set for hourly and eight-hour averages. A typical standard might be 180 µg/m³ for an hourly average and 180 µg/m³ for an eight-hour average.

- Volatile Organic Compounds (VOCs): Regulations may set limits for specific VOCs or groups of VOCs, depending on their impact on health and the environment.

UNITED STATES

Clean Air Act (CAA): Establishes national standards for atmospheric pollutants, including NESHAP (National Emission Standards for Hazardous Air Pollutants) for certain industrial sectors.

INTERNATIONAL STANDARDS

Relevant ISO standards, such as ISO 14001 (Environmental Management Systems), can serve as a global benchmark for managing atmospheric emissions.